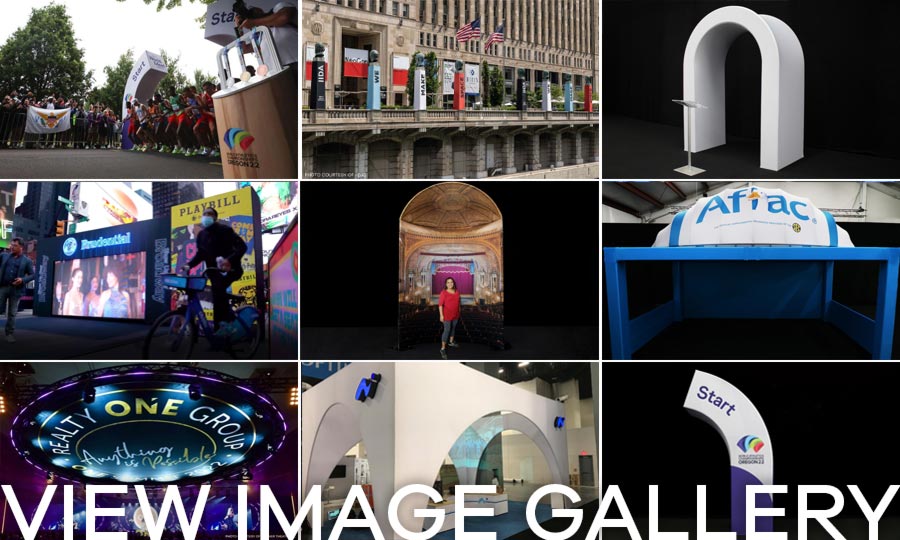

Custom Projects

When our existing Stretch Shapes products aren’t exactly what you’ve been looking for, Custom Projects are the solution you need. Whether you’ve found an item that is similar but you need additional customization, or you’ve dreamt up an entirely new product from scratch, our team is prepared to bring your ideas to life.

Composed of experienced fabricators, sewers, creative designers, engineers, and installers, the Stretch Shapes team is structured to pick up at any point in your creative process. From complete Stage Set Designs to unique standalone pieces, we will work with you to ensure every detail is addressed and the only the highest quality products are delivered.

Our goal with every project is to exceed your expectations and we believe clear communication and prompt response times provide the structure for success. We care about meeting your needs and respecting your budget, so we will listen, learn, and engage with you so we can create the innovative solutions you need.

To deliver the red carpet service you deserve, all custom projects are assigned a dedicated Relationship Manager, who will serve as your guide and representative every step of the way. Designs are finalized and fabricated in-house, to ensure accuracy, precision, and craftsmanship, with all final products tested in-house to guarantee items are correct and designed to perfection.

We are excited to work with you and strive for excellence with each and every project. Please read more about the Custom Projects process below and let us be the trusted source for all of your stretch fabric solutions!

When our existing Stretch Shapes products aren’t exactly what you’ve been looking for, Custom Projects are the solution you need. Whether you’ve found an item that is similar but you need additional customization, or you’ve dreamt up an entirely new product from scratch, our team is prepared to bring your ideas to life.

Getting to Know You and Your Project

- Get to know your Relationship Manager (RM). They are always personal, responsive, and eager to learn about you and your clients’ vision.

- Provide us with your ideas – whether it’s a napkin sketch or finished rendering, your RM will be sure to get the necessary details.

- Tell us what your budget and timeline is – we want to bring your vision to life while still working within your cost.

Let Our Experts Design Your Personalized Solution

- Your Relationship Manager (RM) will bring your project details to the Creative Design Team within 24 hours.

- The Creative Design Team is composed of 3D Modelers, Event Designers, and battle-tested Installers who will collaborate to build the best possible solution for you.

- Your RM will deliver a concept and render (when applicable) to you for feedback and approval.

Approval

- If you do not approve the concept, your Relationship Manager (RM) will take your feedback and requests back to the Creative Team for changes and revisions.

- Once you approve the concept, we will move forward with production and finalizing necessary details, including:

- Payment options and available net terms

- Location of delivery and setup

- Any other relevant details

Producing Your Masterpiece

- Fabricated Frames: All of our robust aluminum frames and bezel-free SEG frames utilize a special industrial coating that protects the frame from oxidizing, so your frame will last for years to come. All frames are built to your specifications and tested to provide stable, true to form projects that never smile.

- Fabric: We work with the highest quality stretch fabrics on the market. Whether it’s the Universal Stretch Fabric or the 100% Blockout Projection Stretch Fabric, we will use the best option available for your custom project to create stunning, wrinkle-free surfaces.

- Patterning: Our talented pattern-smiths design your perfectly fitting fabric skins.

- Cutting & Sewing: A cut above the rest, our in-house cut and sew operation achieves flawless finishes every time, and the Autometrix CNC machine is used for precision and consistency.

- Dye Sublimation Printing: Our skilled Graphics Team uses state-of-the-art, wide-format fabric printing to achieve the high-resolution, photo-realistic prints your customers are seeking. Pantone color matching is also available if needed.

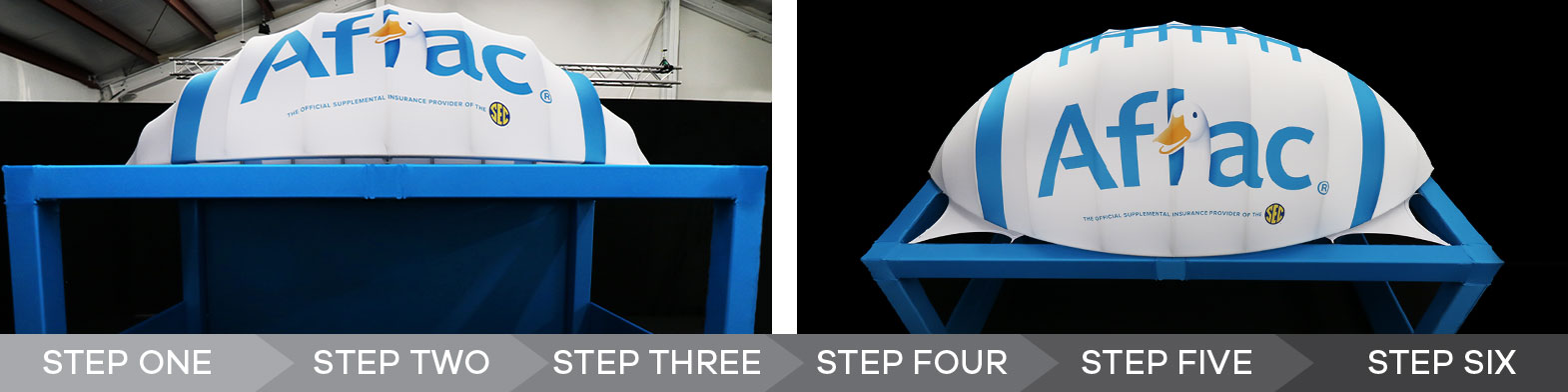

QA, Shipping & Pack

- Your project will be set up and tested in our large testing facility to ensure all items are correct and designed to perfection and ready to perform in the field.

- Shipped in boxes or crates, our logistics team will make certain that your custom project is securely packed, meticulously organized, and delivered on-time.

- Through Quality Assurance testing and careful packing, your order will be prepared to assist in your success.

Installation & Support

- Step-by-step installation instructions are reviewed and included with every custom order.

- Need further assistance? Our team is just a phone call away, and we are ready to help walk you through set up or questions you have.

- Prefer a hassle-free installation? Let our world-class installation team can handle the entire set up and strike for you.